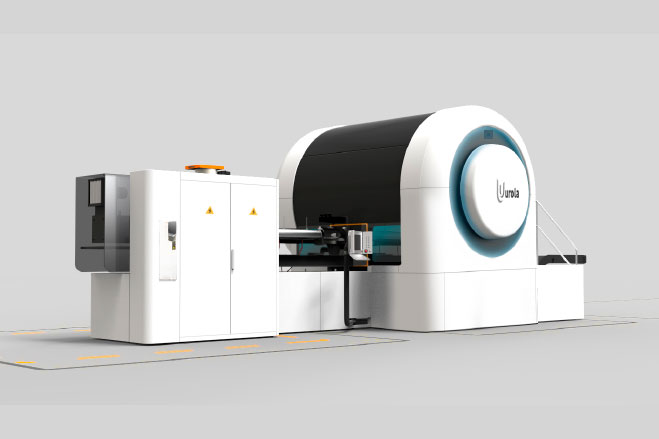

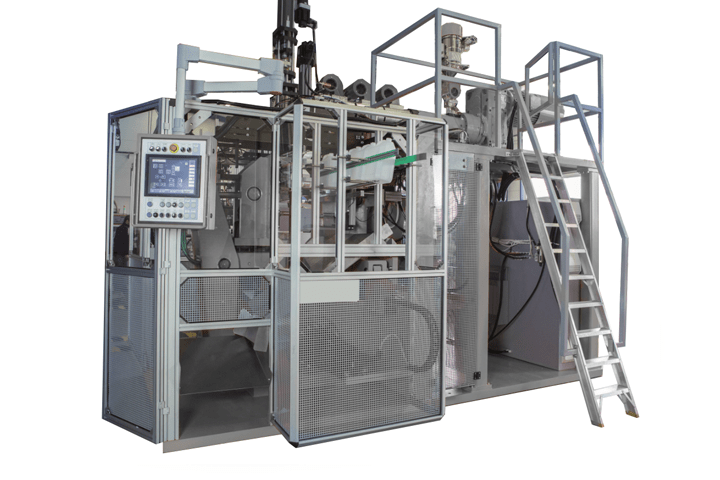

EXTRUSION BLOW MOULDING

ROTARY MACHINES

ROTARY BENEFITS

1. MECHANICAL SYSTEM

Minimum Electric Consumption for Wheel rotation and Mould clamping.

Mould Clamping Force Adjustable according to the container.

Consistency and Repeatability.

System to Raise the Needle Blower for Deep Bases.

2. ENERGY SAVING

At present, the reduction of energy consumption has become one of industry’s priorities.

Urola’s extrusión blowmolding technology is based on a rotary concept, which contributes in a very decisive way to the attainment of these objectives.

This technology allows 30-40% savings in energy consumption in relation to conventional systems.

The explanation is very simple:

-

The moulds are placed in a wheel, where the blow molding action takes place.

The moulds are opened mechanically by the actor of a cam.

It is therefore, a mere fact of maintaining the wheel moving, which needs a minimum energy to do so (4-7kw).

-

As they only have one head, the heating energy in relation to other multi-head systems, is also minimized.

-

We also apply the most advanced developments regarding the extrusion equipments used in our machines, which suppose a dramatic reduction of the energy consumption.

All of these factors together, allow us to obtain values as low as 250wh/kg, a “record” number in energy consumption of extrusion blowmolding equipment

3. INDEPENDENT CAVITIES

Maximum Interchangeability

Minimum Time for Mould Repair

Independent Mould Clamping for each cavity, assuring a Perfect Mould Closing.

4. FLEXIBILITY

Bottles with blown neck: from 100 ml to 2L (keeping the minimum scrap ratio and no change of head).

- Neck to Neck Option

Containers with calibrated neck: from 1L to 10L (keeping the minimum scrap ratio and no change of head).

Easy for CO-EXTRUSION

Possibility to Process a wide Range of Materials.

Minimum mould change time:15 min. per mould.