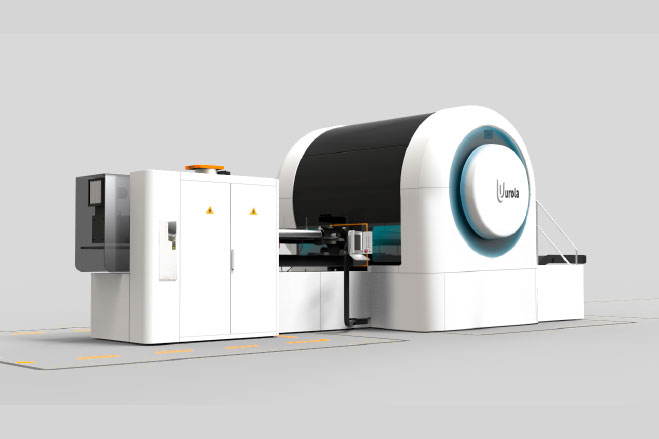

EXTRUSION BLOW MOULDING

SERIE SWT

The SWT SERIES is the new generation of rotary machines with a tangential mould layout in the rotating unit.

Suitable for blown neck containers (without the need for calibration). No external devices are necessary for cutting the parison (such as scissors, etc.)

-

CHARACTERISTICS

Great parison stability at high speeds. Very well-suited for light weight containers including a handle, typical in dairy product applications.

For the manufacture of small containers (up to 350 ml), the NtN configuration (2 cavities per mould) allows for doubling production capacity

Ideal for multi-layer containers.

Maximum mould number: 30 (48 with Neck to Neck configuration).

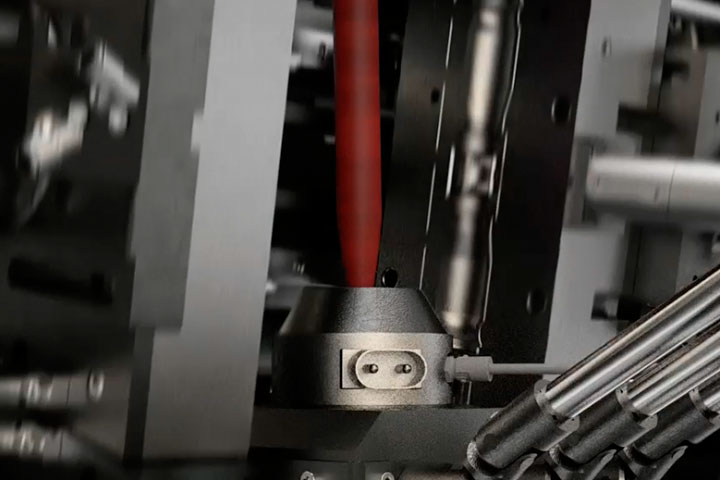

Blown necks (needle blower).

Output: up to 18,000 b/h in single-cavity moulds; 24,000 b/h in 2 cavity moulds.

Comprehensive control system, including parison thickness regulator, with an interface for visualizing process parameters and statistical production control

Integrated deflashing units, either dome trimmer or combination of impact trimmer, dome trimming systems and neck machining.

Container transfer system to integrated deflashing unit.

Completely electric:

- complete control in a single interface

- all rotating valve sequence adjustments are done from the control interface

An advanced extrusion concept with a strong increase in plastification, and notable reduction in energy consumption

High degree of sensorization that allows an integrated control of the operation.

-

ADVANTAGES

SAVINGS OF RAW MATERIAL

Having a single head, regardless of the number of moulds, provides maximum uniformity in the containers, leaving their weight within a very narrow range. This allows reducing the average container weight.

LOW ENERGY CONSUMPTION

A reduced quantity of energy is required to maintain the wheel in rotation and to ensure the final clamping of the moulds. The single head also helps minimize energy consumption, reducing the number of heaters and heads to a minimum.

CPARISON CONSISTENCY AT HIGH SPEED

The parison is always held between two adjacent moulds, allowing for high extrusion speeds even for lightweight containers, assuring total uniformity.

AUXILIARY EQUIPMENT

Because the PEAD blow moulding machine is the basis of a bottle manufacturing line, it is necessary to have access to auxiliary equipment that may be optionally supplied as part of a turnkey project.

CLOSED CIRCUIT FOR MATERIAL HANDLING TO FEED THE BLOW MOULDING EQUIPMENT

Includes:

- Grinders to granulate the scrap generated during the process.

- Raw materials mixing system, masterbatch and regrind material.

- Feeding systems of the mixture to the blower machines.

EQUIPMENT TO PROVIDE THE NECESSARY FLUIDS

- Low pressure air compressor for blower and pneumatic drives.

- Water cooling systems for moulds and other machine services (feeding zone, gear box, etc.)

OTHER EQUIPMENT

- Leak testers.

- Vision systems for control of the produced container.

- Wrapping system and/or palletizing of empty packaging, etc.

- Transport systems to silos or other storage systems.

- Dehumidification systems.

Urola supplies these and ensures their installation through a turnkey concept, taking responsibility for the operation of the line.

MULTILAYER CONTAINERS

Having only one head, regardless of the number of moulds, makes Urola’s rotary machines ideal for multi-layer containers requiring multi-layer heads.

Multiple layer packages capabilities

Multiple layer packages advantages

Barrier properties to protect the product

- To prevent ultraviolet (UV) light from penetrating inside the container and damaging the properties of the product. The typical configuration consists of 3 layers, the internediate, being black one. Used for dairy applications that require long duration.

- To avoid the penetration of oxygen into the packaging where it may cause oxidation of the product, 6 layers are typically needed, as the barrier layer requires adjacent layers with adhesive properties (sauces, mayonnaise, juices, ketchup, some dairy products with added vitamins).

- To prevent the product properties from exiting the packaging (chemical products, etc.). 2 layers are utilized.

Use of recycling

- To take advantage of post-consumer recycled materials. Three layer configurations, with the recycled layer being located in the interior.

Masterbatch reduction

- To minimize the quantity of “Masterbatch”, in cases where the cost is high. The “Masterbatch” is added to the external layer which is thinner than the internal layer.

Coextrusion technology

- To manufacture multi-layer containers it is necessary to install coextrusion systems, whereby the different extruders simultaneously feed the head.

- It is vitally important that the layers maintain consistency both longitudinally and radially to minimize the amount of barrier material.

- In the case of Urola’s rotary machinery, because there is only one head, regardless of the number of moulds, the multi-layer configuration is considerably simplified while at the same time, the required consistency is guaranteed.

- For this, the highest quality multi-layer heads in the industry are used.

NECK TO NECK

With the “Neck to Neck” concept, that is, two cavities per mould, it is possible to duplicate production capacity for small bottles with minimal additional investment.

Neck to Neck technology

NECK TO NECK

Mainly they are used for small containers of dairy products or a “single serve”.

- Two cavities per mould.

- A single blower for both cavities. The blowing is done in the center.

- Transfer to the deflasher via conveyor belt.

- Highly efficient rotary trimmer with horizontal drum.

- Optionally, a system of vertically positioning bottles and a unifier in a single line.

MOULDS

ADVICE

Our service begins with a customer consultation regarding container design, taking the following factors into consideration::

- The product to be packaged.

- Aesthetic factors.

- Suitability for the container manufacturing process.

- Technical characteristics required of the container.

CONTAINER AND MOULD DESIGN

MOULD MANUFACTURING

We use 5 axis CNC Machining Centers and other auxiliary machines for the manufacture of moulds with the highest quality.

SAMPLE MANUFACTURING

This service is covered by Urola when it is required to determine the validity of the container when it is a new packaging development.

AFTER SALES SERVICE AND PREVENTIVE MAINTENANCE

We accompany the customer in the maintenance of the moulds during their useful life to ensure that the conditions of the process are maintained in optimal conditions.

For this we replace worn parts, repairs, check air outlets, check cooling circuits, etc.

A cooling system is integrated within the very mould. Moulds are manufactured in duralumin with stainless steel, treated neck adjustments.