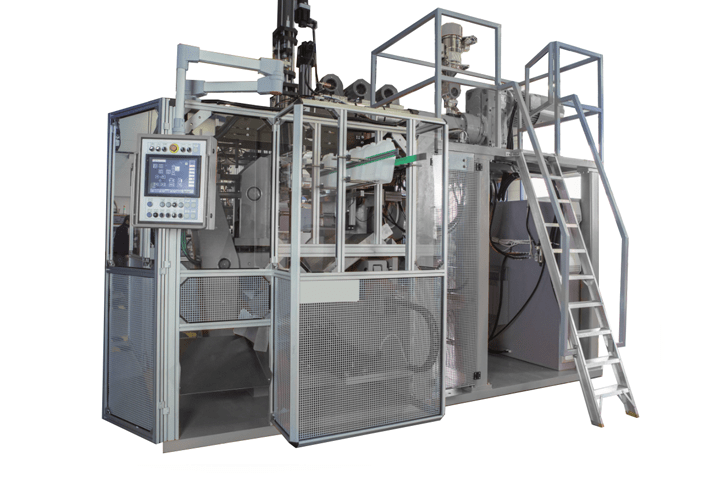

EXTRUSION BLOW MOULDING

URGM SERIES

The URGM series of extrusion-blow moulding machines is based on LINEAR or SHUTTLE technology, suitable for low and medium output requirements.

-

TECHNICAL CHARACTERISTICS

Possibility of manufacturing multi-layer containers and with view-stripe.

Extruder with bobbing movement, equipped with screw driven by AC motor with frequency control for speed regulation.

The speed of the extruder is automatically adjusted according to the parison length and cycle time, ensuring a constant parison length.

All models can be single or twin station.

The press slides on a horizontal motion, driven by servomotors.

Mould clamping action performed by servodrives with final slow down before final clamping. (Except in smaller machines, which are pneumatic.)

Machines can be equipped with multiple heads, depending on the machine type and container dimensions.

Parison thickness control system driven by extremely efficient servoactuators.

Water cooled blow pins.

Integrated control of all functions through a single interface.

-

HIGHLIGHTS

Electric & “Clean” Machine.

Very low Energy Consumption. (As average 25% less than traditional hydraulic systems)

Extremely Compact.

High Simplicity of Operation.

Negligible Maintenance.

-

MAIN APLICATIONS AND MATERIALS

Widely used for the production of plastic bottles and containers from low to medium production rates.

Applications: soaps and detergents, food and beverages, industrial products, chemicals and pharmaceutical products.

Most common raw materials: PEAD, PP, PVC, PETG

MODELS

URGM 250

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 0,25 | 0,4 | 150 |

120 x 45 x 160 |

1 or 2 | 2 or 4 |

URGM 750

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 0,25 | 0,75 | 250 |

220 x 60 x 260 |

1 or 2 | 3 or 6 |

URGM 2000

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 2 | 3 | 300 |

260 x 90 x 320 |

1 or 2 | 5 or 10 |

URGM 2000W

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 2 | 3 | 350 |

320 x 90 x 320 |

1 or 2 | 4 or 8 |

URGM 5000

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 5 | 8 | 380 |

340 x 120 x 420 |

1 or 2 | 6 or 12 |

URGM 5000 W

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 5 | 8 | 440 |

420 x 120 x 420 |

1 or 2 | 6 or 12 |

URGM 20K

| Maximum container volume (L) | Shuttle stroke (mm) | Mould dimensions WxTxH (mm) *2 | No. stations | No. maximum cavities | |

|---|---|---|---|---|---|

| Nominal | Maximum | ||||

| 13 | 20 | 600 |

550 x 200 x 700 |

1 or 2 | 7 or 14 |

NOTE: all machines are fully electric except the URGM 250, which is pneumatic,

Hybrid (electrics + pneumatics) versions are available in URGM 250 models and URGM 750 models

Pneumatic versions are available in URGM 750 and URGM 2000 models

*DEPENDS ON THE CONTAINER TYPE

** THE MOULD WIDTH CAN BE MODIFIED AS NECESSARY

AUXILIARY EQUIPMENT

Because the PEAD blow moulding machine is the basis of a bottle manufacturing line, it is necessary to have access to auxiliary equipment that may be optionally supplied as part of a turnkey project.

CLOSED CIRCUIT FOR MATERIAL HANDLING TO FEED THE BLOW MOULDING EQUIPMENT

Includes:

- Grinders to granulate the scrap generated during the process.

- Raw materials mixing system, masterbatch and regrind material.

- Feeding systems of the mixture to the blower machines.

EQUIPMENT TO PROVIDE THE NECESSARY FLUIDS

- Low pressure air compressor for blower and pneumatic drives.

- Water cooling systems for moulds and other machine services (feeding zone, gear box, etc.)

OTHER EQUIPMENT

- Leak testers.

- Vision systems for control of the container produced.

- Wrapping system and/or palletizing of empty packaging, etc.

- Transport systems to silos or other storage systems.

- Dehumidification systems.

Urola supplies these and ensures their installation through a turnkey concept, taking responsibility for the operation of the line.

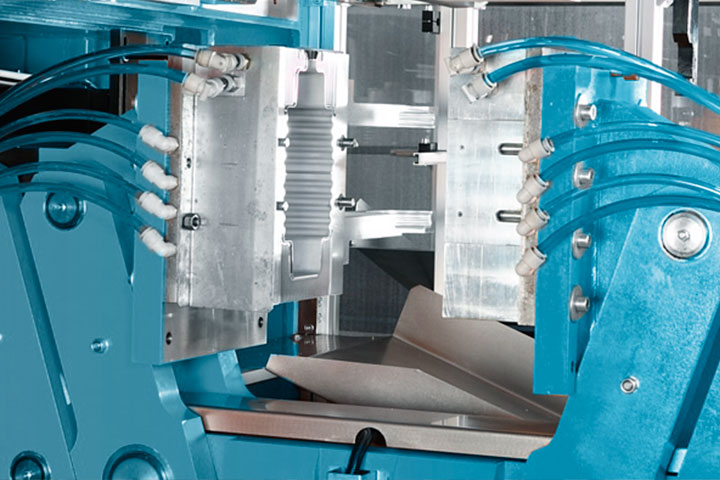

MOULDS

ADVICE

Our service begins with a customer consultation regarding container design, taking the following factors into consideration::

- The product to be packaged.

- Aesthetic factors.

- Suitability for the container manufacturing process.

- Technical characteristics required of the container.

CONTAINER AND MOULD DESIGN

MOULD MANUFACTURING

We use 5 axis CNC Machining Centers and other auxiliary machines for the manufacture of moulds with the highest quality.

SAMPLE MANUFACTURING

This service is covered by Urola when it is required to determine the validity of the container when it is a new packaging development.

AFTER SALES SERVICE AND PREVENTIVE MAINTENANCE

We accompany the customer in the maintenance of the moulds during their useful life to ensure that the conditions of the process are maintained in optimal conditions.

For this we replace worn parts, repairs, check air outlets, check cooling circuits, etc.

A cooling system is integrated within the very mould. Moulds are manufactured in duralumin with stainless steel, treated neck adjustments.