OTHER FOOD APPLICATIONS

Sauces, mayonnaise or ketchup usually require multilayer packaging in order to preserve the product. Cooking oils are typically stored in PET containers.

They are usually oxygen sensitive products. To avoid the use of additives and preservatives, the container must protect the product to prevent from its oxidation.

That is why multilayer structures, were the barrier material is located in an inner layer, are needed.

USED MATERIALS

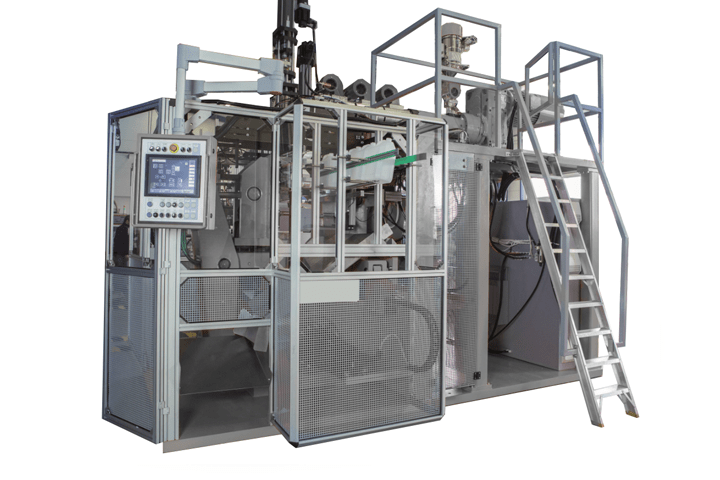

- HDPE, PP. Urola’s extrusion-blow molding rotary concept is ideal for multilayer packaging because it has a single head, which gives a great uniformity and precision to the different layers.

- PET: also in multilayer structures.

EDIBLE OILS

PET packaging is the most widespread, both for small volumes (up to 1 liter) and for volumes of 2, 3, 5 liters. For all of them, we offer the different models of our URBI machines range, very suitable in low and medium cadences, which allows the production of very light containers and in certain designs the generation of fake loops.

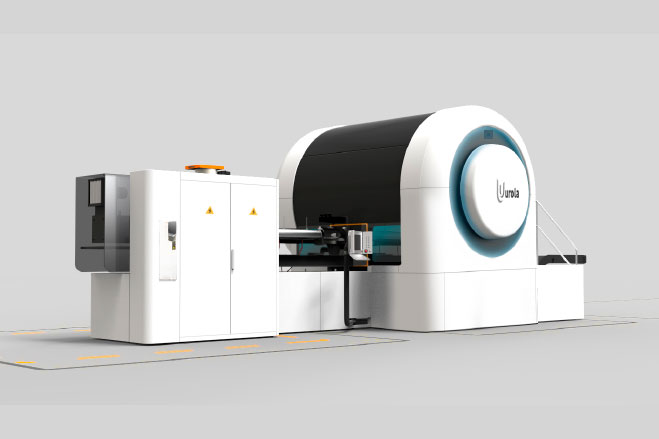

PET BLOWING MACHINES

URBI-4

| No. of cavities | Maximum container volume (L) | Maximum container size (mm) | Maximum Output (b/h) |

|---|---|---|---|

| 4 | 2l | Ø120mm*350mm | 6800b/h |

COMPACT

Very small space in the plant: easy implementation (2.23 m x 3.32 m).

ELECTRIC MACHINE

Servomotors for opening and closing mould-carrying plates, preform stretching and bottle/preform transfer system.

PRECISION HEATING

In each cycle, the 4 preforms leave the oven at exactly the same moment, and unlike other linear systems, no temperature difference is produced between the preforms.

MOULDS

ADVICE

Our service begins with a customer consultation regarding container design, taking the following factors into consideration::

- The product to be packaged.

- Aesthetic factors.

- Suitability for the container manufacturing process.

- Technical characteristics required of the container.

CONTAINER AND MOULD DESIGN

MOULD MANUFACTURING

We use 5 axis CNC Machining Centers and other auxiliary machines for the manufacture of moulds with the highest quality.

SAMPLE MANUFACTURING

This service is covered by Urola when it is required to determine the validity of the container when it is a new packaging development.

AFTER SALES SERVICE AND PREVENTIVE MAINTENANCE

We accompany the customer in the maintenance of the moulds during their useful life to ensure that the conditions of the process are maintained in optimal conditions.

For this we replace worn parts, repairs, check air outlets, check cooling circuits, etc.

A cooling system is integrated within the very mould. Moulds are manufactured in duralumin with stainless steel, treated neck adjustments.