AUTOMOTIVE AND CHEMICAL PRODUCTS

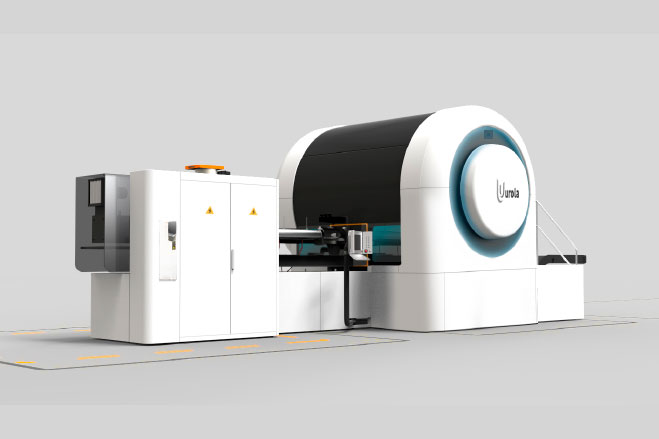

Urola Solution’s two types of container manufacturing technology are adapted for a wide diversity of materials, forms and processes that are required in the containers for automative and chemical products.

Urola’s MSC line of rotary extrusion blow moulding machines is perfectly adapted for this application, offering high quality containers with low production costs.

MOULDS

ADVICE

Our service begins with a customer consultation regarding container design, taking the following factors into consideration::

- The product to be packaged.

- Aesthetic factors.

- Suitability for the container manufacturing process.

- Technical characteristics required of the container.

CONTAINER AND MOULD DESIGN

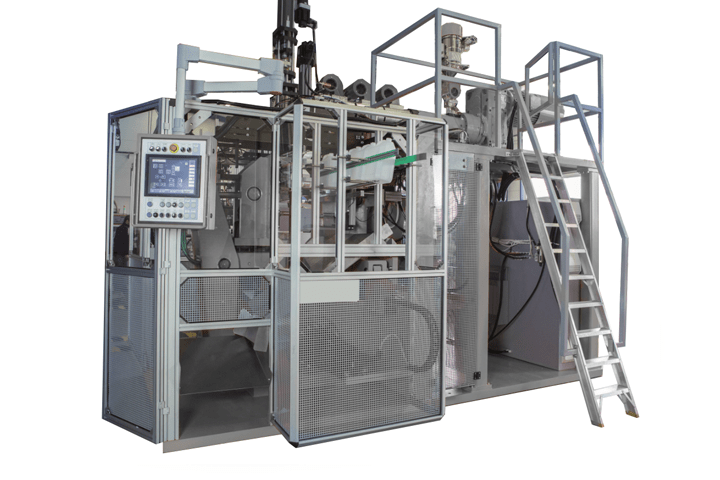

MOULD MANUFACTURING

We use 5 axis CNC Machining Centers and other auxiliary machines for the manufacture of moulds with the highest quality.

SAMPLE MANUFACTURING

This service is covered by Urola when it is required to determine the validity of the container when it is a new packaging development.

AFTER SALES SERVICE AND PREVENTIVE MAINTENANCE

We accompany the customer in the maintenance of the moulds during their useful life to ensure that the conditions of the process are maintained in optimal conditions.

For this we replace worn parts, repairs, check air outlets, check cooling circuits, etc.

A cooling system is integrated within the very mould. Moulds are manufactured in duralumin with stainless steel, treated neck adjustments.