HOUSEHOLD PRODUCTS

Urola Solution’s two types of container manufacturing technology are adapted for a wide diversity of materials, forms and processes that are required in the containers for household products.

The two types of Urola technology for packaging manufacturing are adapted for the wide diversity of materials, forms and processes that are required in the containers for personal care and household products.

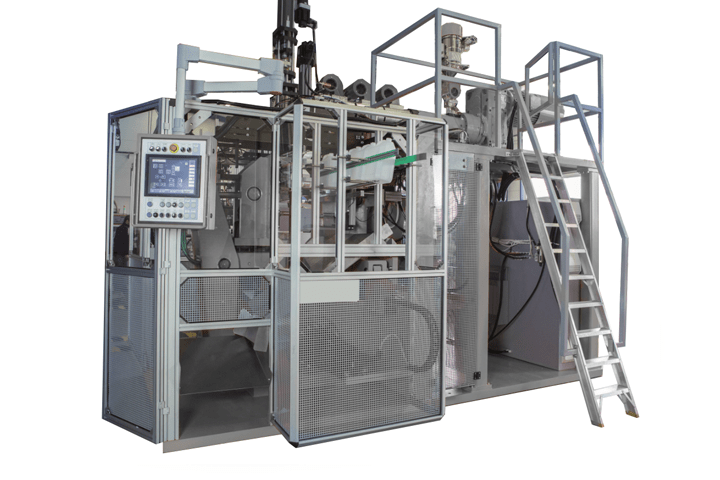

For PE and PP bottles by extrusion blow moulding, the Urola rotary machine models are appropriate when requiring needle blow and calibrated neck packaging of at least 1-2 litres. Special mention should be made regarding the possibility of adapting the calibrated necks to blown necks, with the advantages that they offer.

Similarly, in PE or PP packaging using a pearlescent masterbatch for improved appearance, multi-layered structures (two layers) are useful as they decrease the required amount of this additive. For this, our rotary technology is highly appropriate as it only requires the use of one multi-layered head.

Oval shapes are frequently used in PET bottles. Our system of preferential heating, a simple and practical concept, is the ideal tool for creating this type of containers. Whether it is equipped at the origin or at a later time.

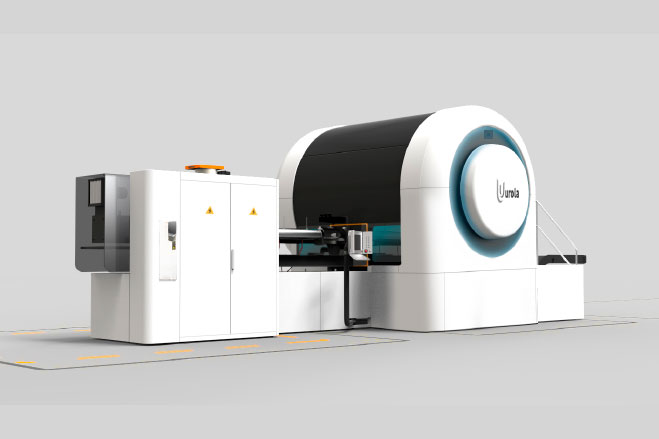

PET BLOWING MACHINES

URBI-2L

| No. of cavities | Maximum container volume (L) | Maximum container size (mm) | Maximum Output (b/h) |

|---|---|---|---|

| 2 | 8-10 l | Ø200mm*400mm | 2500b/h (5 litres) |

COMPACT

Very small space in the plant: easy implementation (2.23 m x 3.32 m).

ELECTRIC MACHINE

Servomotors for opening and closing mould-carrying plates, preform stretching and bottle/preform transfer system.

ENERGY SAVINGS

Reduced air consumption thanks to high efficiency of the oven and electric drive systems as well as the air recovery system.

URBI-4

| No. of cavities | Maximum container volume (L) | Maximum container size (mm) | Maximum Output (b/h) |

|---|---|---|---|

| 4 | 2l | Ø120mm*350mm | 6800b/h |

COMPACT

Very small space in the plant: easy implementation (2.23 m x 3.32 m).

ELECTRIC MACHINE

Servomotors for opening and closing mould-carrying plates, preform stretching and bottle/preform transfer system.

PRECISION HEATING

In each cycle, the 4 preforms leave the oven at exactly the same moment, and unlike other linear systems, no temperature difference is produced between the preforms.

MOULDS

ADVICE

Our service begins with a customer consultation regarding container design, taking the following factors into consideration::

- The product to be packaged.

- Aesthetic factors.

- Suitability for the container manufacturing process.

- Technical characteristics required of the container.

CONTAINER AND MOULD DESIGN

MOULD MANUFACTURING

We use 5 axis CNC Machining Centers and other auxiliary machines for the manufacture of moulds with the highest quality.

SAMPLE MANUFACTURING

This service is covered by Urola when it is required to determine the validity of the container when it is a new packaging development.

AFTER SALES SERVICE AND PREVENTIVE MAINTENANCE

We accompany the customer in the maintenance of the moulds during their useful life to ensure that the conditions of the process are maintained in optimal conditions.

For this we replace worn parts, repairs, check air outlets, check cooling circuits, etc.

A cooling system is integrated within the very mould. Moulds are manufactured in duralumin with stainless steel, treated neck adjustments.